In the early days of engine design, poppet valves (that we all have in our four-strokes bikes today) needed frequent decarbonisation, and springs were notoriously unreliable. An alternative invention for getting fuel/air in and exhause gases out was the sleeve valve.

In 1909, James Harry Keighly McCollum was granted a patent for ‘an Invention of Improvements in and relation to Valves and Valve Gear for Internal Combustion Engines’.

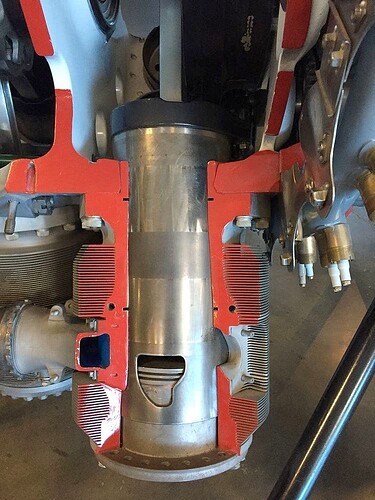

A sleeve valve takes the form of one (or in the case of double sleeve valves, two) machined cylinders which fit concentrically between the piston and the cylinder block bore of an internal combustion engine having cross-flow induction/exhaust. These sleeves have inlet and exhaust ports machined in the periphery, analogous to a two-stroke motor. Ports in the periphery of the sleeves come into alignment with the cylinder’s inlet and exhaust ports at the appropriate stages in the engine’s cycle.

There was a competing patent granted to Peter Burt just a few weeks later for a similar design that resulted in a combined ‘Burt-McCollum’ sleeve valve.

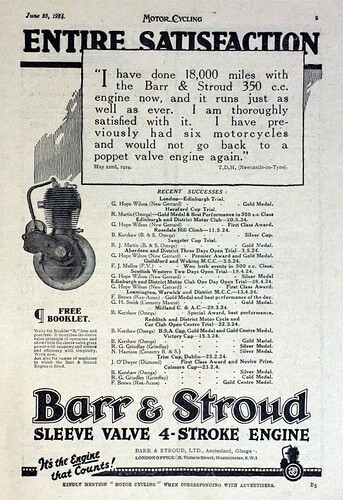

Barr and Stroud of Anniesland, Glasgow, licensed the single sleeve valve (SSV) design, and made small versions of the engines that they marketed to motorcycle companies. In an advertisement in Motor Cycle magazine in 1922, Barr & Stroud promoted their 350cc Sleeve Valve engine and listed Beardmore-Precision, Diamond, Edmund, and Royal Scot as motorcycle manufacturers offering it.

Grindlay-Peerless started producing a SSV Barr & Stroud engined 999cc V-twin in 1923 and later added a 499cc single SSV as well as the 350cc.