Carrying on

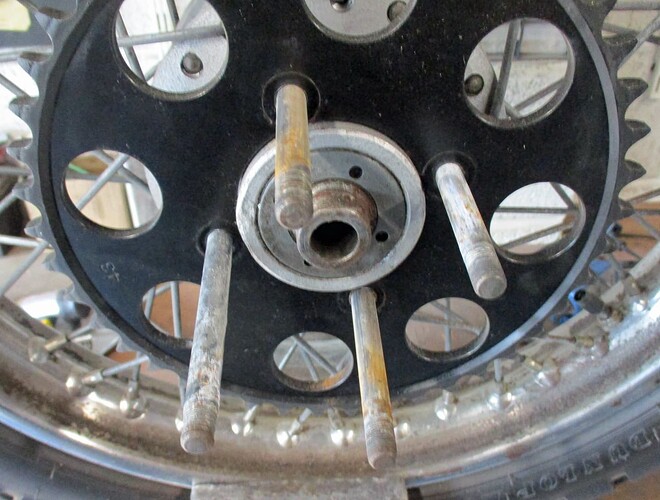

Instead of just cutting the spokes I had some idea to maybe reuse them so unscrewed each nipple and took them all apart.

Note how I’ve kept the spokes labelled so I know where they came from off the hub. Rear rims on T140s are offset (that is, the centreline of the hub is offset from the centreline of the rim). This is to keep the swingarm narrow so there’s no need for a spacer for the rear sprocket and allows the chain to run straight without eating the tyre while keeping enough space for a disc on the other side. (Think I’ve covered myself there  )

)

As the rims are offset the spokes have to different lengths. The spokes will also have slightly different angled bends to allow them to connect to the rim:

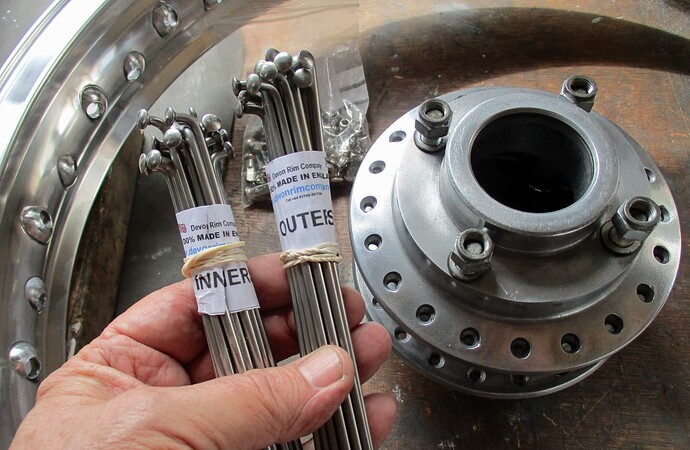

That’s cleared up why the spokes are sorted, it helps when rebuilding. They can be sorted fairly easily if required - new ones come mostly all jumbled up in a single bag. And there’s not really much of a difference in length or angle in new ones - they are easily cut and bent to suit if needed. So don’t get too worried about all the part numbers etc if ordering new ones. Just order T140 front or rear spoke sets.

Moving onto the front:

This rim looks pretty good but there are those dimples in the chrome showing that it will be lifting soon. There’s nothing you can really do with chrome rims, they stash water away that no amount of cleaning will prevent the eventual lifting. Clean too much and the thin layer of chrome will rub off to expose the copper below. I’m afraid the spokes are the same, these however are zinc coated and should clean up if not too rusty (normally on the bends where they sit all wet in the hubs).

I now only ever buy polished alluminium or stainless rims.

I only very rarely find wheels, IMO, built correctly these days. This is one of the rare ones built by someone who knows what he/she is doing. Note that the outer spokes, on both sides of the wheel run in the same direction. Nearly every wheel I’ve seen have the outside spokes running in opposite directions, which IMO is incorrect.

Here’s one of my front wheel builds:

As we all know the tread on the front tyre ‘points’ backwards. This is because it’s needed that way when applying the brakes, it’s the direction of greatest load. Which is why front spoked wheels have the outside spokes also ‘pointing’ backwards.

I get that lacing wheels is a bit of a mind fuck but if time is taken and enough thought is given (really difficult in my case, it takes me ages to work myself through it) it can be done correctly. I’ve no doubt that it probably makes no difference at all to the loading but it’s the correct way in my mind.

Similarly the back tyre will have it’s treads ‘pointing’ forwards. Which is how the outer spokes should be built. This is really important due to the absolutely massive power output from the mighty T140 (almost as much horsepower as your iphone  )

)

Spokes come in different thicknesses - thinner 10g and thicker 9g. The spindly 1.85 rims on the front had the 10g which will not be much good in the sexy Italian rims on their way so it’ll need to be new spokes all round then.

Onto the now released hubs:

These are off of a 1978 bike. As everyone was trying to save costs in those days due to the shrinking Empire the hubs are painted with a silver hammerite paint. Obviously now lifting with some corrosion to the alluminium underneath.

So, paint has to come off and alluminium polished a bit. This takes flippin’ ages and is a right git to do. There’ll be sore fingertips for the next few days.

I’ve done half of the front hub and almost half of the rear today. Notice how the hub halves look the same but the rear has an extra centre piece to get more width - be careful if ordering hub parts, they are not all the same.

I’ll save the next fun filled sanding polishing day for tomorrow. Such fun…over

![]()