Ignition timing, innit  …with an old Boyer Branston pickle ignition system.

…with an old Boyer Branston pickle ignition system.

I’ve had one of the Boyer systems hanging around in the stash since about 3 builds ago. It must have come off a running bike otherwise I would have binned it so thought I’d use it on this build…

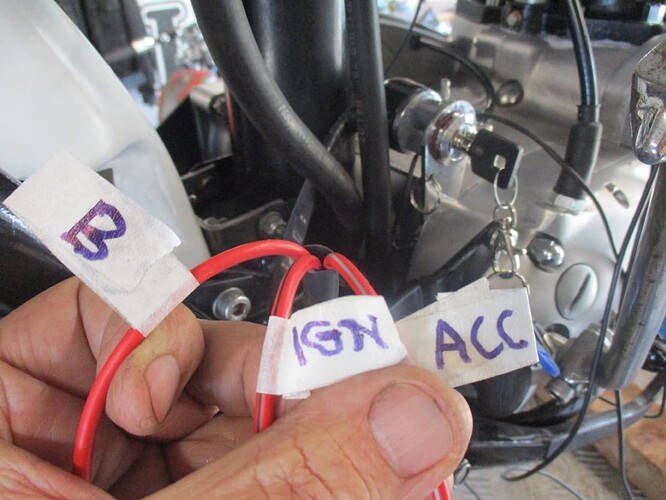

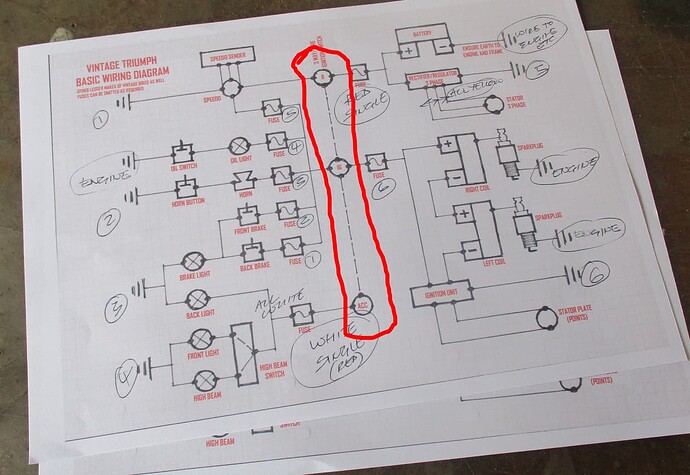

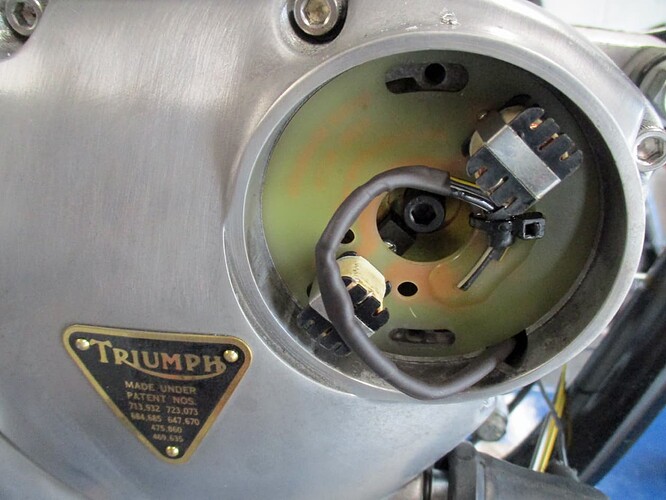

There it is - the red box - under the seat unit all wired in. Pretty simple to wire in:

White wire is Earth, Red wire to positive side of right coil, Black wire to negative side of left coil and the other two wires off to the stator plate (where the points used to be).

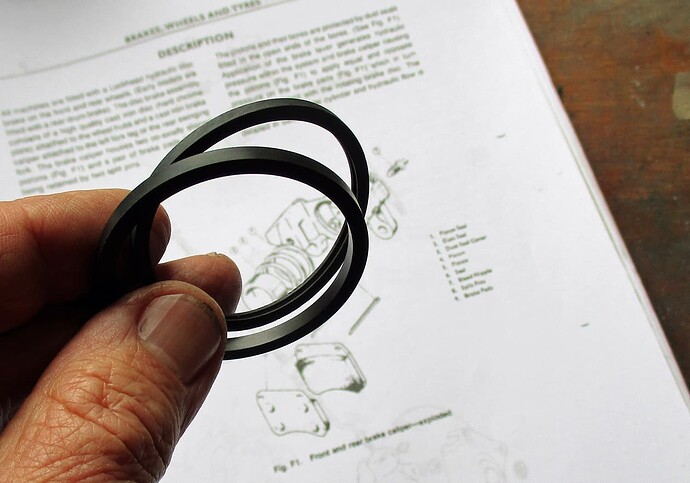

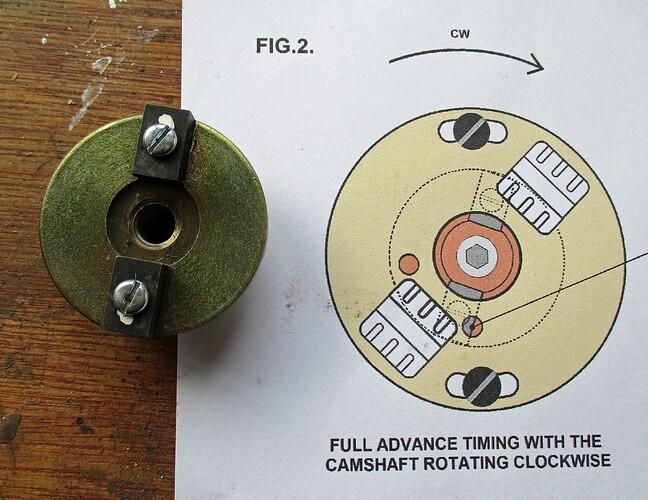

The Boyer/Branston stator plate is on the left. In comparison to the Wassell Vape system I usually use on builds.

The Vape system is one that I’d blown the ignition unit on a previous build by not earthing the engine (took me ages to work that one out) but the stator is fine as a spare.

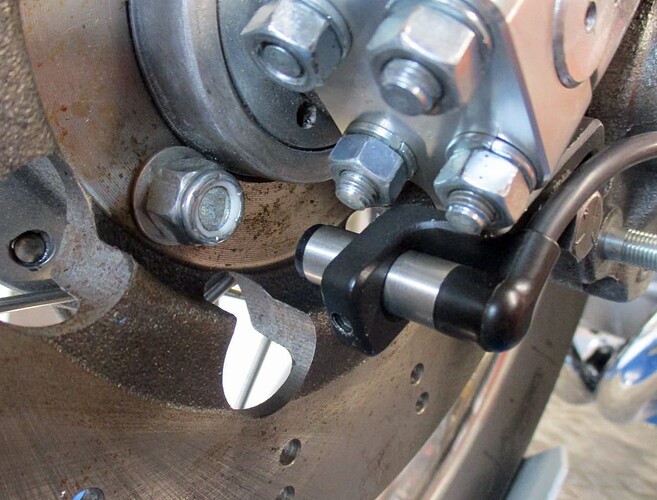

To help with the timing throw an old chain on so the back wheel can be used to turn the engine over - saves trying to do that with the kickstart or a spanner on the crank.

Raise the back wheel off the floor using a jack or a very strong wife so the wheel can can be turned by hand.

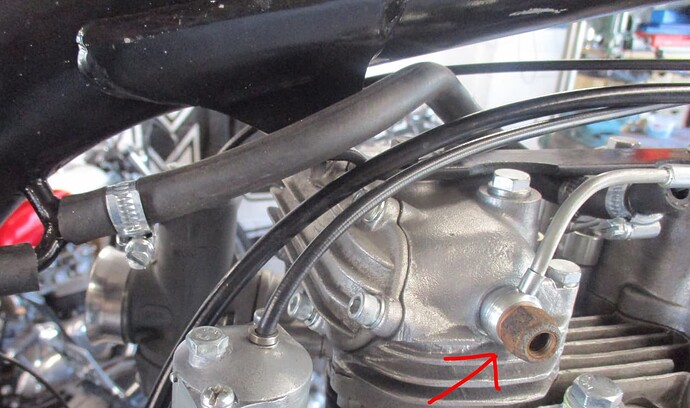

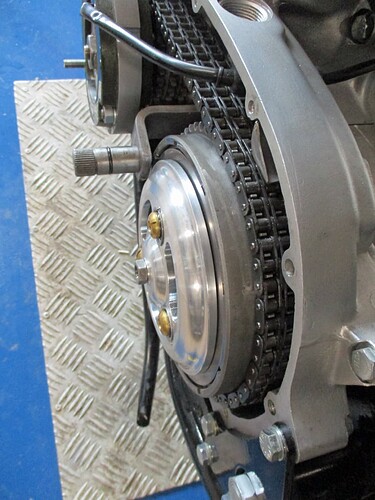

Take the timing access plug out of the crankcase just behind the barrels. This gives access to the crankshaft flywheel. The flywheel has two slots built into it which can be found through this access.

The slots will be directly under this hole when at Top Dead Centre and at 38 degrees Before Top Dead Centre.

Right, another small explanation - sorry Grannies and Eggs.

The fuel/air mixture is sucked into the combustion chamber through the carburettor by the piston moving downwards and the inlet valve opening.

This mixture is then compressed by the piston moving upwards and then ignited by the sparkplug. It’s therefore quite important that the plug sparks at just the right moment to get the best performance from the engine.

However, a fuel/air mixture does not combust instantaneously. It actually burns relatively slowly.

For an engine to be efficient, as much of the inflammable mixture should be burned as is possible.

The sparkplug causes the flammable gas to start to burn, it burns in a sort of ouwardly expanding wave, starting at the spark and moving across the combustion chamber in all directions.

It takes time for the majority of the burning expanding gas to be at it’s greatest force to push the piston downwards on it’s power stroke.

On these vintage Triumphs the engineers worked out through design and trials that the greatest efficiency was obtained by sparkling the spark plug just before the piston reached it’s highest point, in fact at 38 degrees Before Top Dead Centre.

Other engines, racers, clever clogs etc may use other times to spark their spark plugs but a standard T140 runs best all round when it fires the spark plugs at 38 degrees before Top Dead Centre. This gives enough time for the fuel/air mixture to burn as much as possible before it’s all pushed out via the exhaust valve through the Zorsts by the rising piston on it’s journey through it’s four strokes.

It’s obviously a bit more (well, lots more actually) complicated than that but that’s the jist of why engines need to spark when they do.

Phew, sorry about that. Back to our rebuild.

First thing to do when sorting the ignition timing is to find Top Dead Centre (TDC). That’s when the piston is at it’s highest point. But also should be on the piston’s compression stroke.

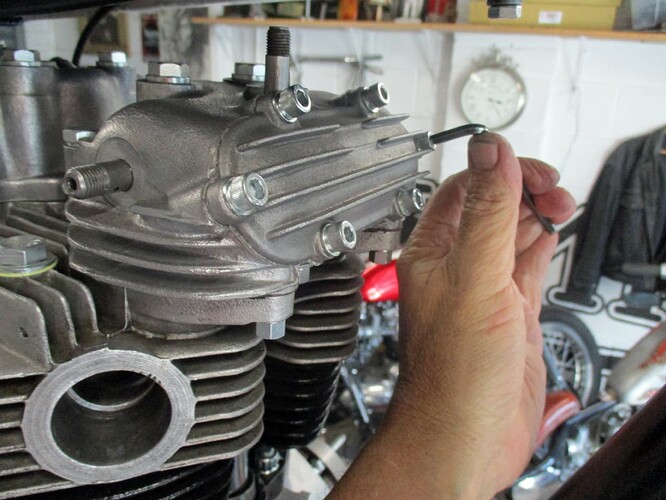

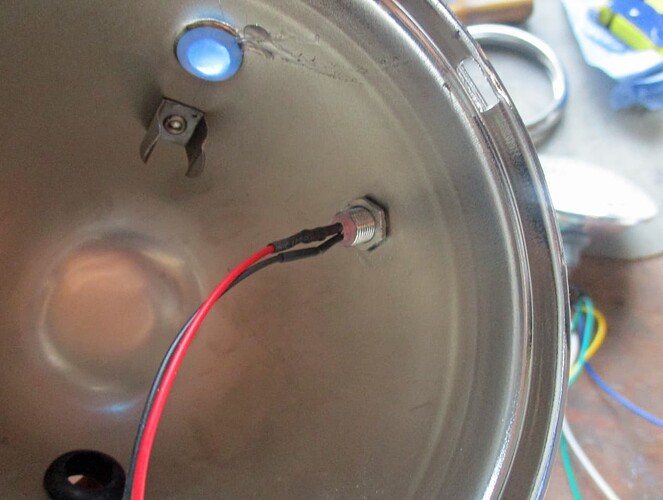

This is looking down the right hand sparkplug hole.

The shiney thing below the screwthread is the inlet valve in it’s open position (that’s when it’s letting the fuel/air mixture into the combustion chamber)

The engine can be kicked over while looking down the sparkplug hole until the inlet valve can be seen, the piston is then on it’s compression stroke.

The engine is put into 1st or 2nd gear.

A long thin thing can be held down the sparkplug hole to feel for the top of the piston (I do have a long thin stick for this but I seem to have lost it).

The engine is turned over by moving the back wheel as though the bike was moving forwards therfore turning the engine over as it would when running. Note the T140 engine normally runs clockwise.

The piston will move upwards, do this slowly as the long stick thing will get jammed if you are not careful.

Feel for when the piston is at it’s highest, move the wheel forwards and backwards to feel for piston movement. This method finds TDC pretty accurately - better than those screw in measuring stick things.

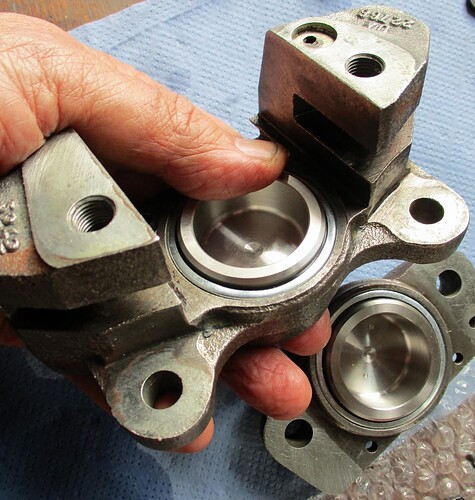

Stick another feeler thing (not your finger as it’ll get stuck) this is a posidrive screwdriver into the timing hole in the crankcase. Feel for the flat of the crankshaft flywheel. Move the back wheel again fowards and backwards until the feeler feels the slot in the crank.

Try the level of the piston again.

The engine is now at TDC.

We’re looking to find 38 degrees Before TDC. This is where we’ll tell the engine to fire using it’s electronic stator plate (points).

Move the wheel backwards. This moves the engine backwards as we want BEFORE TDC. The ignition has to start BEFORE the piston gets to it’s highest point to allow time for the fuel to burn.

Sorry about the shouting but it’s easy to get confused.

So, move the wheel backwards in little hits while feeling the flywheel/crankshaft move under the feeler in the timing hole. Keep going until the feeler slips into the 38 BTDC slot.

The engine is now where it’s needed to be to set the ignition timing.

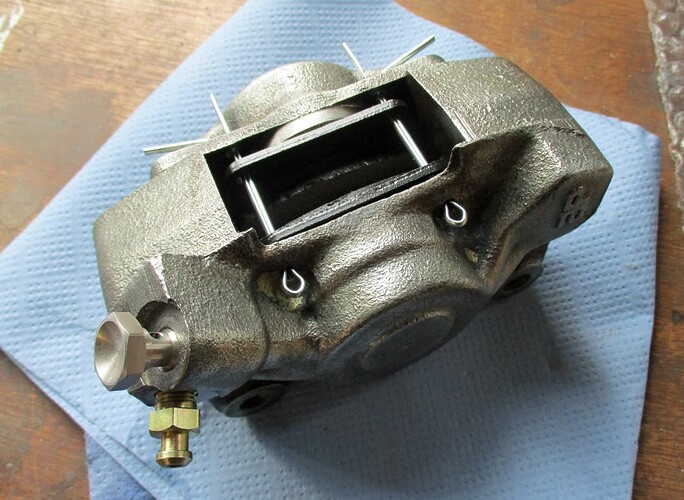

On left hand gear change T140s there’s a little opening in the primary cover with a pointer. The pointer will be at the timing mark on the rotor. Here it’s spotty dog right on the mark.

I just temporarily slotted the primary cover on for this.

These will be marks used when strobe timing once the bike is running.

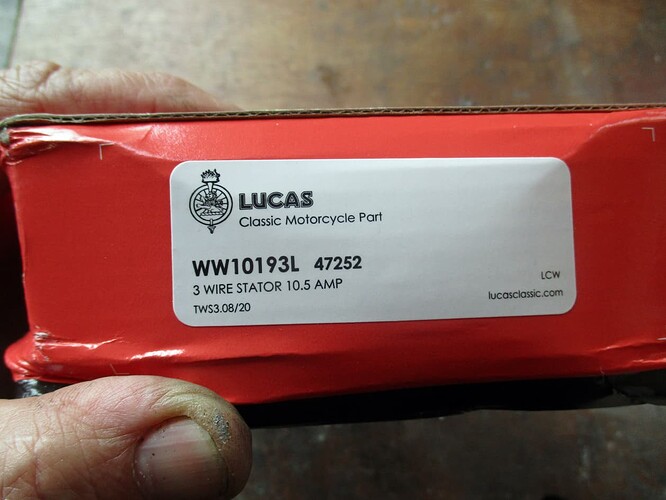

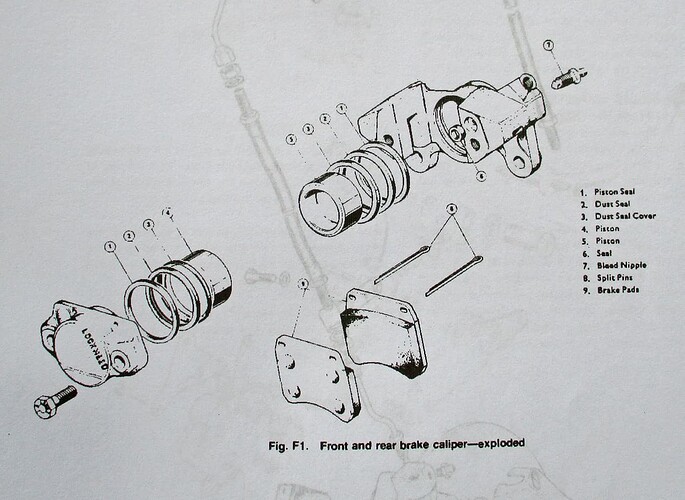

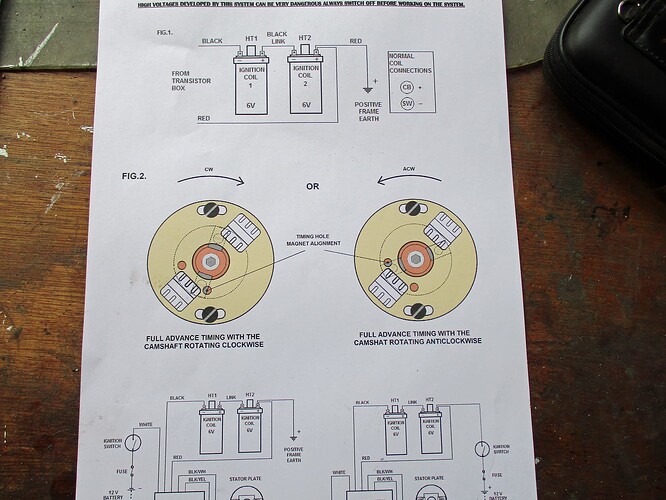

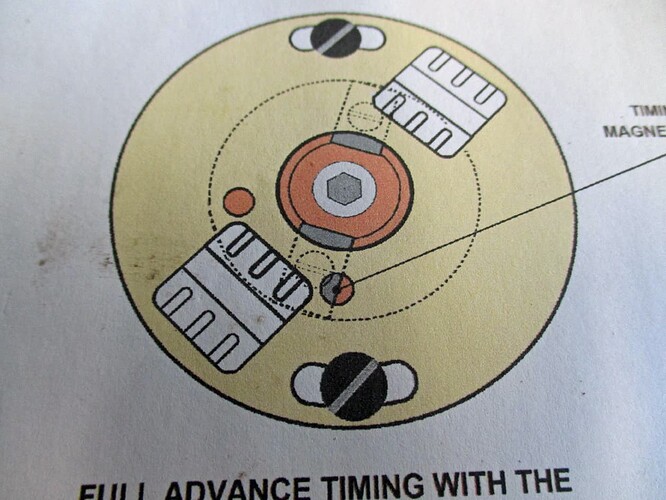

I downloaded the instructions for the Boyer Branson unit. There’s a long list of each model available on their website.

Note there’s a difference for clockwise or anti-clockwise running engines. Horrible BSAs and Nortons run that way for some stupid reason.

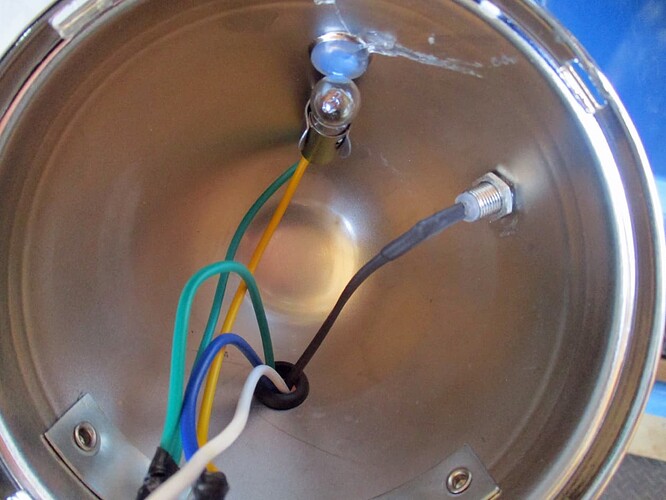

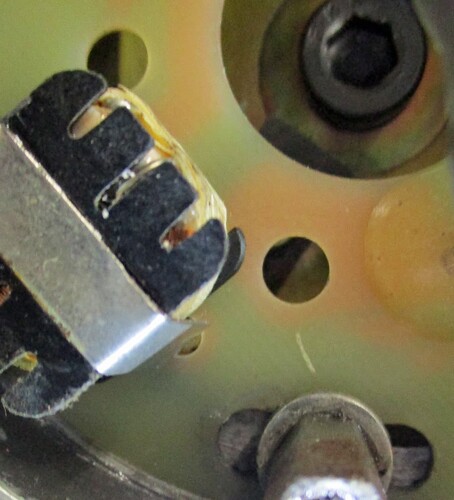

Here’s the moving plate with magnets and it’s correct position on the diagram. I think someone had painted little white dots on the magnets already. Although I don’t think they are needed looking at the instructions.

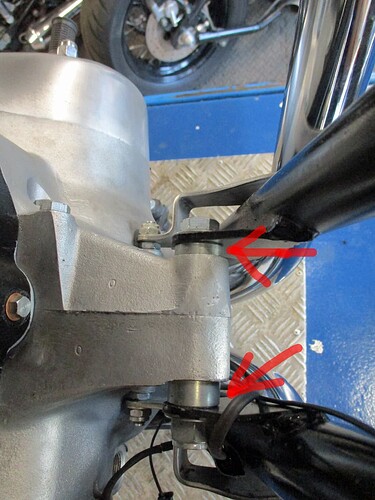

The plate is lightly screwed into the end of the exhaust cam so it can be moved to set it correctly once the front plate is positioned and secured.

I didn’t like how the bullet connectors were made to be under the points cover. So I duely cut them off and soldered extra lengths onto the two wires so the connections can be outside where I can see them. I’d like to easily check if they’ve come disconnected if the bike conks out.

Here’s the stator plate with the white dot on the magnet peeking through the ‘clockwise hole’. I’ve no idea why that’s printed on the back where it can’t be seen.

But the instructions show that the magnet’s edge should be halfway through the hole. There’s no sign of a white paint dot.

So, that’s where I’ve set it. I’ve no idea if it should be the white dot or as the instructions show but I’ll go with the instructions. Tighten up the bolts.

If the bike runs but the timing is a bit off it’ll be fairly easy to sort by slackening off the pillar bolts and moving the plate.

So, that’s that. Ignition timing should done so found a groovy points cover and put that on.

![]()

![]()